How it Works

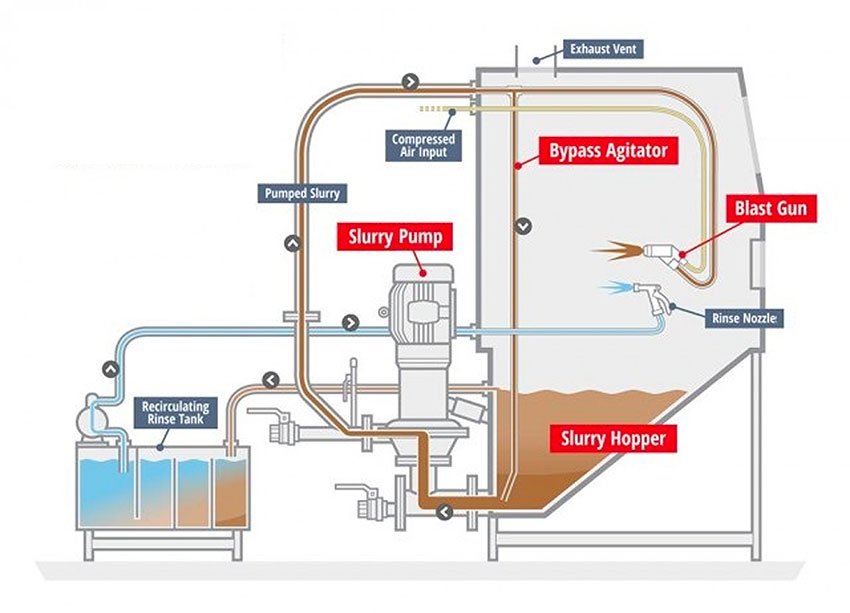

Vapour blasting is also known as wet blasting or liquid honing, and it is very popular in Britain for bike restoration. The process creates a slurry of micro beads, water, and air, and then this is propelled at high speeds towards the surface of a metal part. This seals the surface with a micro finish that helps it resist staining and oxidation, so not only does it restore, but it also protects. The water used in this process has a hydraulic cushioning effect, which softens the impact of the micro beads on the surface of the metal, and provides a lustrous satin finish. Finishes will vary from different alloys and manufacturers, but all are good. Aluminum castings are particularly well suited to vapour blasting, and have a fantastic outcome.

How do I prepare my parts for Vapour Blasting?

Disassemble the parts, removing any brackets, bolts, or any other ferrous metal parts you can. Threaded steel inserts, iron cylinder liners, valve seats and or pressed-in bearing surfaces obviously can’t be removed, we will mask thesebefore blasting and immediately clean and treat these with protectant to prevent flash rust.

Clean and remove the worst of any grease and oil etc. before sending parts, or you will be paying us to clean them ), adding time and expense to your project. Gaskets and heavy sealants must be removed prior to blasting – the blaster will not remove them and if the parts are not cleaned prior to blasting the blaster will be contiminated.

Our Process

- Discuss your project with you and set your expectation.

- Receive components.

- Visually inspect the components.

- Inform you before going ahead and make note.

- Test a small area with the aquablast to ensure compatibility and expected outcome.

- Vapour blast components.

- Rinse thoroughly and blast dry with compressed air then heat gently and blast with air again.

- Apply anti corrosion inhibitor.

- Final inspection of finished components.

- Arrange return/collection of components.

CALL 0413 053 001 for a FREE Quote